Increasing workplace productivity is a hard thing to master. But it can have a massive impact.

What would your output and bottom-line look like, if productivity was improved by 10%?

What about 20%

What about 50%

60%?

100%?

The more productivity gained, the more your business and customers benefit.

There’s a bit of a science to increasing workplace productivity.

Some of the time management remedies you may have heard, talk about simple techniques like:

– Create daily tasks and to-dos

– Understand your goals

– Get organised

Other articles provide tips on general HR topics, like:

– Improve motivation

– Set expectations and behaviours

And so on.

The problem is, they are stating the obvious. They all have a part to play, but there’s an angle that’s often overlooked.

Increasing workplace productivity starts with processes.

What’s needed is a system or framework that can be followed to actively target non- productive tasks within processes.

And then set about eliminating them.

Every business has them.

Whether you’re a manufacturing company, producing landing gear, a solicitor providing no claim no fee services, a customer services call centre, a photography business, or anything else.

Every business has a range of processes or activities that they must complete in order to provide a product or service to the customer.

Within these processes lay many different forms of waste.

It’s this waste that reduces productivity.

It’s this waste that also has an impact on morale. So reducing waste in every process can have a drastic impact on increasing workplace productivity.

It can improve your processes and staff morale, because things are now appearing to get fixed.

People are being heard.

Far too often, members of staff feel stifled and not listened to. They spot issues and report them, but nothing ever seems to get done.

It’s not because managers don’t want to help, it’s because they don’t normally know how to correct so many problems, if they get raised.

There’s no system.

Increasing workplace productivity is about working to a clear framework.

Process Problems? Let’s Talk About Turn-backs

Some of the real productivity issues in the workplace come from things I call Turn-backs.

Turn-backs stop you from increasing workplace productivity.

Increasing workplace productivity: Identify all the small Pebble sized problems when they happen.

They are everywhere in a business, and are often hidden.

Think of them as little pebbles…

In the context of our rock analogy, issues tend to be small pebble-sized problems at the time they arise.

The problem is, they tend to get lost in the day-to-day operations of business.

In many instances, people create quick fixes and make do with them, absorbing the pain themselves, and just putting up with them.

But they rarely get the issues fixed.

And the longer each issue is not addressed, the bigger they become over time.

The bigger the issues become, the more they impede productivity and add to organisational chaos and strife.

It gets worse. If you don’t have a system that can identify and correct issues when they arise, you get the equivalent of death by 1000 cuts.

Often, businesses become crippled by the shear overwhelming effect of all these mounting issues.

Eliminating turn-backs is at the heart of increasing workplace productivity.

Turn-backs are all the things that prevent you from completing a specific task.

Imagine how many tasks there are in your business.

There are literally hundreds or even thousands.

Imagine how many times your people get stopped from doing these tasks because of impediments to flow?

Let’s Look at an Example

If we were working in a data entry centre, tasked with entering data and verifying key fields of information as they flash up on screen…

we may experience some of the following turn-backs:

If some of the forms that pop up on screen, are missing important bits of data, preventing us from verifying them…

This would slow us down. The worst case is that it may stop us, totally.

The same is true for the following examples:

The wrong application forms are given to us

The wrong job is set up on our system

We don’t know what to do next – we haven’t been instructed by our team leader

The IT system fails

We keep getting incomplete data

The point is, anything, no matter how big or small, which prevents this activity being completed, is a turn-back.

It’s an impediment to flow.

It stops you completing the task. (or slows you down). This results in productivity losses.

The same is true for any process, no matter what it is.

From processing enquiries, to making widgets, to paying employees or suppliers, to designing products or services to customer requirements.

Where there’s a process, there are impediments to flow, or turn-backs, which only act as productivity inhibitors and cost the company extra money in time and lost opportunities.

In fact, there are so many of these hidden productivity blockers that if you could highlight them all, gather them up and measure their impact in your business, you’d probably be terrified by the amount of time lost by them.

Increasing workplace productivity: A typical process with turnbacks

Imagine your processes being a certain length expected length of time.

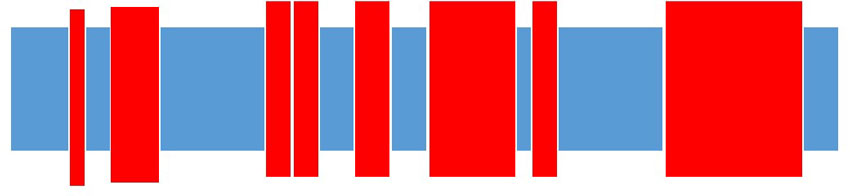

It’s represented as the blue line in the diagram above.

Turn-backs are those that stop the process from running or slows the process down (the red elements in the diagram).

The result being: a much longer process time from start to finish.

If you could ideally eliminate all your turn-backs, you would have a faster and more productive process (below):

Increasing Workplace Productivity: Remove the Turnbacks and reduce the effort and lead time of the process.

Increasing workplace productivity is all about making it your team’s or business’ mission to actively hunt for turn-backs and eliminate them.

And getting your staff to help do this.

The true power of increasing workplace productivity is to get everyone in your team or business, to take action.

Everyday.

In some way or another, to help reduce turn-backs.

But first, let’s explore how you reduce turn-backs…

Increasing Workplace Productivity by Reducing Turn-backs

If you’re able to see the turn-backs affecting each team, then you can do something about stopping them, or reducing them at the very least.

So how do you identify them, and manage them systematically?

First you have to find and then prioritise them…

Pareto’s Law

Pareto’s law, or the 80/20 principle states that the majority of problems come from the minority issues, or the vital few.

When you’re looking for turn-backs, you want to find the 20% root causes that effect the 80% problems.

Here’s an example of what I mean:

In the CNC section of a company that makes general nuts and bolts, one of the main machines keeps breaking down.

As a result of this, the business loses 20 hours per week of productivity.

The problem is that when it breaks down, it appears that many different things keep going wrong.

The program isn’t right

The spindle stops working

The jaws malfunction

The conveyor belt stops

And so on.

These are all individual problems, but they are not the root causes. They are symptoms of a bigger, more deep routed problem.

The root cause is where you’ll find the true turn-back or the reason for all these failures.

It’s the vital few cause(s).

The team could carry on fixing problems when they pop up, or invest a little extra time looking for the true root cause, so they can put it to bed for good.

In this example, the team conducted some 5 why questioning, and found that it’s because the machine isn’t serviced regularly.

Regular care and preventative replacements of parts is not happening and the machine effectively runs until parts break, forcing a reaction to get it working again.

Here’s the improvement opportunity: If the machine had a regular service plan, then you would be able to prevent most of these failures from happening.

The same is true for any process.

If you can measure it, and then monitor when things go wrong, you can work backwards to find the root causes, when they happen.

By doing this throughout your business, you can set about drastically increasing workplace productivity.

Shiny Ball Syndrome

Before you run off and make it your mission to eliminate your entire turn-backs, it’s worth prioritising first.

Otherwise you’d sink in the shear myriad of so many problems.

Remember, prioritising to find the 20% root causes, is critical. It allows you to attack the biggest problems, first. In order to do this, you need data around you…

Here’s the simple 4 step system to help get clarity, focus and productivity gains.

It will allow everyone to work together and become empowered to provide laser sharp focus on the vital few causes.

Everyone has a part to play to become empowered and take action with the view of increasing workplace productivity.

The 4 Step Process to Increasing Workplace Productivity

4 steps to increasing workplace productivity

Step 1: Create your Leading Metrics

There’s an old saying in the business improvement world that, “what gets measured, gets improved.”

If you don’t have a handle on your metrics and how you’re performing right now, then how can you possibly hope to improve?

Even if you have a gut feel that things aren’t right…

– How do you know with certainty?

– How do you know where to start (with an accurate estimation)?

– How do you know what success will look like, when it’s improved?

– How can you get a true picture of the voice of the problem?

The bottom line is that you don’t have enough information to make great decisions.

Opinions are good, but they’re not enough.

Having data is where the magic happens.

You do this by understanding the voice of the process (VOP).

Find your Leading Metrics

There are two types of metrics:

Lagging metrics – those typically at the end of a process which tell you how it all went. They are delayed metrics.

These could be things like:

– delivery performance yesterday / last month / last quarter

– quality rating yesterday / last month / last quarter

– number of customer complaints

– lead time

– Health and Safety Stats

And so on.

They are good indicators to show you what HAPPENED.

In support of these lagging metrics, you need what’s called “Leading Metrics.”

They are key metrics that you need to measure in as close to real time as possible, to ensure that the end result will go to plan.

To ensure delivery performance is right.

Or the quality is to plan.

Or there are no issues which’ll carry customer complaints…

To put it another way, the leading metrics have a direct impact on the lagging metrics.

If your leading metrics are all to plan, then, by default, your lagging metrics will be, too.

Here’s what I mean:

In a Warehousing facility I once walked around, the manager told me that he measured all his KPIs.

Sure enough, he had touch screens everywhere and tracked:

– The number of picks yesterday (versus plan)

– The customer returns for the day (if any)

– What needed to go out today

– What actually went out yesterday, against plan

Apart from the today’s planning, above, the other three metrics are lagging metrics.

They show you how the overall process(s) did, yesterday.

What was missing were leading metrics. These metrics will help gauge whether the distribution business is on track, DURING the day.

And not having to wait until the next day to find out.

So, the question here is, what could be the leading metrics?

In this case, the two key in-process metrics could be:

– The Picking rate vs target – Is the team matching todays picking rate demand?

– The Picking accuracy vs target – Is everything picked right first time? If not, it’ll incur additional delays.

– Number of picks against daily target – What’s the total cumulative target, and where are we as the day unfolds?

These metrics are critical to the output of the overall process, which is shipping all products on time. They would show the health of the process, right now.

And, just as importantly, if the metrics drop off, you would be able to respond quickly, to get them back on track, thus ensuring that the leading metrics are on track each day.

This is one of the major mistakes most businesses make.

Some manage to track their performance, but only focus on the lagging metrics.

By focusing on leading ones too, can have a drastic improvement in increasing workplace productivity.

Because, if you can see issues effecting your key processes, in real-time, you can act on them in real time.

If you’re in a garden nursery, propagating plants, it could be; the number propagated to plan, grow rate to plan, gestation period to plan, and so on.

If you’re in the solicitor business, it could be:

– The number of instructions to plan

– The number of completions out by work type, to plan

– The amount of work in progress to plan

You get the picture.

The point is this:

You have to understand the key process metrics that will tell you how you’re doing in real time.

What are your leading metrics?

Use this template to think about a key process in your team or business.

A template to help you brainstorm your leading and lagging process metrics

What are you trying to measure – what does success look like?

Now work backwards and look for the leading metrics. The ones which are critical to providing the outcome.

Step 2: Monitor your processes

The second main step in increasing workplace productivity is to simply monitor these metrics.

With all the good work completed from step one, you now have an understanding of what to measure.

In this step, you need to work out how to measure your key leading metrics, so they can pass what I like to call, the 30-seconds test.

And that is…

- Your metrics should be so clear to see, that a stranger can walk into your work area and be able to see within 30 seconds (and without asking anyone) how you’re performing to plan.

- These metrics must be easily updated. In fact, when I say this, I mean they should be updated within seconds, and no more than 30 seconds.

If you can update them quickly, and they are clear to see, then you’re onto a bit of a game changer.

But you must involve your team members.

Get them to brainstorm and work out how to update and record these metrics CLEARLY and EASILY.

They will be the ones responsible for updating, maintaining and running with them.

One of the easiest and effective methods of monitoring your metrics is through whiteboards.

They are cheap and easy for a team to design.

And when they have tried something, they can re-design the board based on their next iteration for improving what they’ve got.

Use What Works for You and Your Business

Now, some industries may struggle with this, and sometimes using software may be the right solution for a specific environment.

For example, a data entry centre may be better equipped with software that monitors their leading metrics.

But in many situations, a whiteboard is more than enough.

But use what works best for you and your team.

Here are some examples of simple but effective whiteboard tracking:

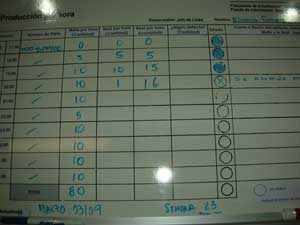

Notice the simplicity of this board. You don’t know the business, it’s history, what it does and you certainly don’t know the process.

But you don’t need to.

What you can see is all you need to know as a stranger; and that is current status of the process.

In this instance, it’s not running to plan.

It’s hard to see, due to the flash of the camera, but in the centre, there is a box showing “Std/Act”, meaning the standard versus actual results.

The Red and green status cards are a great way of making status visual to see, too.

We’ll touch on the power of using Red / Amber / Green Status for increasing workplace productivity, shortly.

Here’s another.

In the same principle as before, you don’t need to know the ins and outs of the process.

- The first column with numbers in is the hourly target of units produced

- The middle column is the actual number of units produced

- The third column with numbers, represents the cumulative units produced, so far.

- On the far right, there’s the status circle.

(The slight improvement I would make to this, would be to include a cumulative target next to the cumulative actual, but I’m splitting hairs, here.)

In this example, the process is falling behind plan. It’s now time to take critical action (if they haven’t done so, already!)

Making your Metrics visible is imperative to increasing workplace productivity.

When you do measure your leading metrics, the magic happens:

You can see whether you’re on target

As a result, you can start to get yourselves organised, and ready to tackle the problems when they pop up.

And then get the teams to act on these issues when they first see them, which is the next point…

Step 3: Spot the Turn-backs

You now know what turn-backs are. It’s now time to do something about them.

And in this step, you’ve just made it easier for yourself, because you can start spotting them with ease.

Remember, a turn-back is something that impedes flow to a process. This flow impediment often results in targets being missed.

The great thing is, we have just set up a simple system which tracks your critical in-process metrics.

And now they are visual and clear for everyone to see.

Any variations to plan can be instantly jumped on.

When you or your team do spot a metric that fall’s short of the plan, there are two critical things to do:

- Understand what has gone wrong and take a note on the visual board or the system you’re using.

- Look to get back on track as quickly as possible, even if that means putting a plaster on the problem, for now.

the-traffic-light-system

And the best way to show current status with any metric is through the Red, Amber, Green system:

- When your metrics are to plan, then place a green against that metric.

- When you’ve experienced a problem, which may affect your output, then it’s amber.

- If you’ve missed your target, then it’s an instant red.

This visual technique is so powerful and easy to do.

It allows everyone to manage by exception: To see the processes that are currently struggling and then to work together to quickly respond and correct issues.

I remember a General Manager of a large American company I was working with.

After he received some training on this topic, he instantly came back and said to all his team leaders, “I want to be able to walk the business and see status.”

He got his teams to create their visual boards with RAG status on, and positioned them in a way that he could see them all, when he set foot in each area.

He wanted to see the red; amber; green status, so he could then hone instantly in on the ambers and reds.

With any ambers or reds, he would then ask questions to his supervisor and their team, like:

- “What are you doing about this problem?”

- “How are you getting back on track?”

- “When do you expect to get back on track?”

- “Do you need any support from me?” (Note – be prepared to act quickly and decisively, not promise something and walk away, and never follow up on your actions)

These four key questions are pretty powerful.

They’re about getting the team members taking the responsibility to update their metrics, and spot issues when they arise.

They also have the responsibility to update the Red; Amber; Green status, to tell the team and the business when there’s a problem.

The team leader’s role is to respond quickly to ask these same 4 questions to their teams, too.

This ensures that there is good two-way commination and support; and a system to respond to problems.

Now, if there is a big problem that can’t be resolved at the team leader’s level, then they have to raise it instantly to their line manager, so they can help.

But this process of monitoring, visualising problems and then correcting them is vital to increasing workplace productivity and getting everyone on board, at all levels.

Now picture in your mind’s eye, that this is now an everyday system. A habit that the teams are doing.

What’s the next thing?

Fix the Problems Through “Root Cause Analysis”

You should now use root cause analysis to identify the main problems affecting your impediments to flow.

A simple way of doing this is through the 5 why’s analysis.

By getting your teams involved in spotting deviations to plan…

And when things are not going to plan, making it clear to see…

The team can begin to correct problems when they arise and quickly get to the root causes.

So rather than just making do, stop to address the real root cause and then create a plan to get back on track.

In some instances, the team may not be able to solve the problem they’re facing.

In this case, they pull on the support of the next manager, to help support them and to close out the root cause.

If your team or business did this systematically every day, could you see the improvements that can be made?

So far, we’ve looked at measuring current status and addressing the problems when they arise, but when step 3 is in place, it’s time to look at solving longer term problems…

Step 4: Conduct Longer term improvement projects

So, now you have an idea of what’s working and what’s not in your processes.

Your team are responsible for monitoring using the 30-seconds rule.

They are spotting and acting on the turn-backs when they arise.

Line managers to the supervisors check in regularly to view the status of the in-process metrics in their areas.

And when there’s a problem (Amber or Red), each manager and supervisor asks the same 4 key questions across the business:

- “What are you doing about this problem?”

- “How are you getting on track?”

- “When do you expect to get back on track?”

- “Do you need any support from me?” (be prepared to act quickly and decisively, not promise something and walk away)

The next step is to get all the teams in your business to understand their top turn-backs over time.

You want to create a culture of every team or department being able to understand their top 20% turn-backs, which are causing the majority of problems.

Here are two examples of what your turn-back charts could look like.

The first is a hand-drawn board, updated by the staff when a problem occurs:

Pareto chart – example 1

In this graph, it’s just a case of operators updating by hand and then reviewing these problems over time.

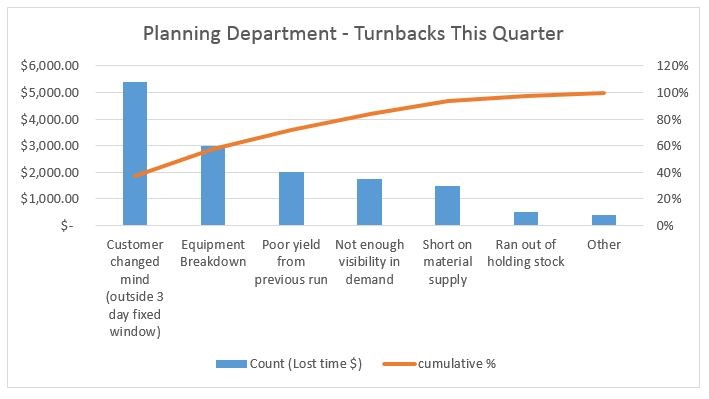

The second is an Excel Alternative. The count on the left hand side measures impact instead of count.

It’s your choice whether you want to measure count or some type of impact.

Count is easier, but it can be misleading.

(You may have a turn-back that happens more than another, but its impact could be less.)

Pareto chart – example 2

In the instance of the above, you can clearly see that 80% of the impact comes from the three main turn-backs:

- The customer keeps changing their mind, outside the agreed 3 day fixed window (this would be the main focused project)

- Breakdowns

- Poor yield from previous run

These 3 things would be the area of focus to help increase workplace productivity.

Here’s a Pareto Chart Template that you can use to measure your quarterly turnbacks.

Now, you have good data, which shows the biggest turn-back for each team or department.

The next step is to organise quarterly turn-back sessions with each team.

Each team reports their top turn-back and presents a mini project plan to try and tackle their 20% root causes.

These charts and action plans should be displayed in each area, so everyone knows what their biggest problems are and the current turn-back they’re working on.

These projects are longer term, and take as long as needed to eliminate or reduce their impact on processes.

But the simple act of reviewing processes (leading metrics) and taking action to keep on track every day, and also stepping back to review the biggest problems per quarter, is a powerful way of creating a continuous improvement culture.

Imagine if your entire business was following this simple 4 step approach?

I’ve yet to find a business that doesn’t benefit from it!

Increasing workplace productivity – Don’t forget your templates:

Other Articles You May Like