Plan Do Check Act is a framework that was created by quality guru, Edward Deming as a way of structuring problem solving and continuous improvement.

It’s simple in its approach but very powerful in its delivery.

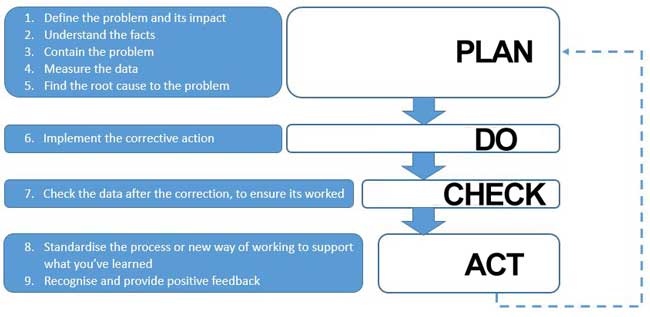

The generic steps of PDCA are:

Plan – Identify the problem, where you want to be and gather the facts. Start to define the reasons and get to the root causes.

Do – Implement the improvement and test.

Check – Check it’s worked and review the data

Act – If it’s worked, standardise the improvement. If not, tackle the next problem and repeat PDCA again.

This process forms the backbone of a continuous improvement culture.

In fact, Toyota who helped pioneer this method, has built their whole ethos and success around it.

One of their mantras is that everyone in the organisation should make improvements based on the scientific method, under the guidance of a coach.

That scientific method is the “hypothesis”–”experiment”–”evaluation” process, that’s used over and over again. The Plan Do Check Act cycle is a reflection of this.

And everyone adopts it, using the support of a coach or their leader, to help them implement improvements, daily.

Systematic Plan Do Check Act Process

Plan Do Check Act can be used for many different scenarios. In fact, where there’s a problem, it should be used to eliminate it. And it provides a framework to solve it in a structured way.

The role of the coach is to ensure that the PDCA model is being used correctly and people are learning the method. And that they also understand their own processes and systems.

If they understand them by observing and measuring data, they can be best placed to make informed and accurate improvements.

The coach also ensures that they don’t jump to conclusions too soon.

This is a common problem that most inexperienced practitioners make. And it leads to incomplete solutions.

Problems come back, repeatedly .

Plan Do Check Act and 2 Different Reasoning Patterns

Deep within this framework lies two key problem solving techniques:

- Inductive Problem Solving

- Deductive Problem Solving

Inductive problem solving starts with data and generates theories based on that data.

Deductive problem solving starts with theories and proves the theory applies.

So How Does it all Fit?

Using the plan do check act approach, you bind inductive and deductive problem solving together.

The Japanese approach of problem solving and making decisions is to ‘go see’. This means go to the place the problem happens (or the improvement needs to happen), and observe.

By observing and understanding, you learn more about the problem.

Based on your observations, you then make some theories to test and understand more.

And based on the outcomes, you learn.

You can learn by proving that your deductive reasoning hasn’t worked. And by this, I mean, what you thought should have happened, didn’t.

In this scenario, you go again, study the data by using inductive reasoning, and find the next idea that’ll improve the situation.

This is repeated, until you improve the situation and solve the problem.

When you do, you lock the improvement in and standardise the process to ensure the problem doesn’t return.

By following this journey of observing, and analysing data (inductive reasoning) and then making theories on what’s happening (deductive reasoning), you can fix problems and keep them that way.

Plan Do Check Act Model

The Plan Do Check Act model incorporates both of these reasoning modes.

One of the mistakes that many inexperienced problem solvers make is that they just go with their gut feel and focus all their efforts on making judgements…

Without stopping to verify and use the data to support this.

What often happens is that problems tend to come back.

And fixes are normally temporary.

The plan do check act framework allows you to follow a structured way of improving. Using both inductive and deductive reasoning.

Ttaking time to see what’s actually happening when the improvements made. Adjusting, based on the results.

The 9 Step Process to Effective Problem Solving, Built Around Plan Do Check Act

When you encounter a problem, here’s what you can follow, using plan do check act as a guide:

- Define the problem and its impact – Start with identifying what’s wrong; what’s the current state? What’s the problem and what should it all look like in an ideal world?

This first stage of the plan do check act cycle is about understanding the problem, right now. Once understood, it’s time to take note of what it should like, if the problem wasn’t there.

- Understand the facts – This is the inductive problem solving part. Watch, observe and measure the problem with data, first.

What exactly’s happening? What’s the data saying? Are there any trends? Is it happening at certain times of the day / week /month? How often does it happen? Get as much data as possible to allow you to make informed deductive reasoning.

- Contain the problem – As there’s a problem happening right now, this next step is to ensure the problem doesn’t get any bigger. If it’s a process problem, the main aim is to ensure it never reaches the customer.

Containing the problem means taking action to minimise the impact. Limp through whilst you give yourself time to observe and conduct the long-term fix.

- Measure the data – It’s now time to delve deeper into the inductive problem solving phase.

This is done by observation and analysis. What actually is happening? Where is the process failing? What’s the data saying? What are the trends?

- Find the root cause to the problem – You’re now in a position of knowledge. You’ve observed and analysed what’s happening. You’ve also created a list of the many potential root causes.

It’s time to take things a little further by drilling down to find the root causes. Some simple but effective ways (but not the only way) of doing this is the use of the Fishbone Diagram and the 5 Whys analysis.

The point is to identify the root causes and create a plan to eliminate them.

- Implement the corrective action – Here’s where you apply the heavy lifting. You’ve looked at the problem; analysed the data, contained the problem and identified a root cause.

It’s time to commit action to overcome the root cause. What things need to be completed to put it to bed?

During this phase of the cycle, you’ll complete your action plan to do just that.

- Check the data after the correction, to ensure its worked – This is pretty self-explanatory. It’s now time to observe some more, and to see if the solution has worked or not.

In the grand scheme of continuous improvement, you’ve learned either way.

If the problem is still there, then you know that what you thought it was, actually wasn’t the case. So it’s time to go again and re-evaluate, passing through the Plan – Do – Check – Act phases again.

If it did work, you’ve also gained a deeper understanding and should now be in control of things.

- Standardise the process to support what you’ve learned – Now, you must extrapolate the lessons learned and lock in the change. In most instances, this would entail a process change of some sort.

Standardising means changing whatever needs to be changed and making it the new way of working. You do this to control of the process. And so, you ensure the problem doesn’t come back.

- Recognise and provide positive feedback – Celebrate a job well done; congratulate the team and let everyone know of the achievement.

Remember, to lead well. Communicate, empower and provide feedback!

This is a particularly forgotten element of continuous improvement and good leadership.

So don’t forget to give people a pat on the back for demonstrating the right behaviours and achievements during the project.

Here’s how these 9 steps fit within the Plan Do Check Act framework:

plan do check act framework

Where can You Use Plan Do Check Act?

You can use this method in every problem your business has.

It could be in identifying persistent perpetual errors that keep happening in processes, no matter how manual they appear.

In fact, the common reasoning when people make errors is to just settle for it being a human error.

The PDCA method can show you another way of looking at things.

And if you adopted these 9 steps, you’ll be pleasantly surprised that this assumption your human error conclusion can turn out to be something that can be controlled more readily.

You can also use it to coach your teams in making improvements.

In mature, lean environments, leaders should coach the PDCA framework, empowering teams to make their own improvements.

Leaders do this by asking 4 key questions to the teams, and getting them to internalise and provide answers around the plan do check act cycle:

- What is it that should be happening?

- What is actually happening?

- What’s the biggest obstacle you’re going to work on improving?

- When can we go and see if it’s worked?

These four questions help coach the plan do check act framework across the organisation.

Plan Do Check Act Can be Used Across All Parts of the Business

The PDCA model can quite literally be used anywhere in the business.

In fact, if you’re serious about implementing a continuous improvement culture, then it must be used everywhere, and at all times.

Other areas that structured PDCA can support improvements, are:

- Improving productivity

- Reducing customer complaints in the same common failings

- Improving staff engagement

- Improving profitability

- Reducing process downtime

- Improving quality

- Reducing cost

- Improving delivery performance

- Eliminating waiting of work

- Improving morale and staff engagement

And many others that you may have thought of yourself.