A3 problem solving is a standard way of presenting problems and resolutions. It has the name A3, as it’s simply an A3 size piece of paper (international 11”x17” / 29.7cm x 42cm).

Its inception was part of the Toyota Production System. And is a means of providing a standard framework to present problem solving, projects, and status reviews.

Its effectiveness is in the fact that everyone in the organisation uses it and that due to its simplicity, it can be read and understood by everyone… Quickly and easily.

What’s important is not the document itself but the process and thinking behind it.

A3 Problem Solving’s Simplicity

A3 problem solving’s power is that in one A3 size piece of paper:

You can create a story of what’s going on…

what you intend to do…

and where you are right now… All on one sheet of paper.

You can have several A3 problem solving documents running at the same time, each focusing on a specific problem solving project.

Each presenting information easily and in a standard way.

In A3 problem solving, less is more. Complexity is not a mark of clear thinking.

Simple, to the point visuals are easier to grasp and understand… Other benefits are:

- It provides a clear presentation of the facts

- It’s an objective view of the data at hand

- It provides a specific and rational conclusion

- And short and long term plans, too.

Thus, there’s less time wasted on flash PowerPoint presentations, which take up excessive amounts of time trying to decipher information.

Or overly complicated reports that have far too much information. Thus, wasting more time reviewing and trying to understand information.

A3 Problem Solving Helps Steer You Through the PDCA Cycle

The A3 problem Solving document is also an easy way of guiding people through the Plan Do Check Act Cycle (PDCA) in a standard way, so that everyone can follow, routinely.

It has pre-conceived sections which require detailed thought of the problem at hand, from:

Plan – What’s the problem? What should success look like? What’s the root cause(s)?

Do – What needs to be done by when? What are the countermeasure steps?

Check – When can we go and check it’s worked? And how is the problem performing now? Has it gone?

Act – What are the actions and follow ups that need to be done to ensure the problem is eradicated? Did the problem return, when we checked it? What’s the next thing we need to do?

Why Use A3 Problem Solving?

Most problems that arise in organisations are addressed very superficially.

We merely provide a work around to the problem that’s faced, so we can keep going.

If you’ve ever read 7 Habits of Highly Effective People, you’ll know what I mean.

In it, there’s a story of a man walking through the woods, and he hears a lumberjack sawing away at a tree, whilst cursing in frustration.

He asks the man, “What’s the matter?”

The man replies, “I’m trying to cut this tree down and I have loads more to do, but the saw is too blunt.”

“Why don’t you sharpen the saw,” the man replies.

“Well, I have too much to do and not enough time to stop.”

The man walks away, shaking his head.

You and I both know that what the Lumberjack should do is stop and take the time to sharpen the saw. That investment of time will help with his effectiveness in cutting down trees.

Now, in the book, it refers to us spending time to sharpen our own saws. To be the best we can be by planning our time effectively.

In problem solving the same is true.

Most companies superficially attack each problem, when it pops its ugly head and merely look for quick workarounds, to keep going.

Taking time to stop and go through a structured, logical way of addressing it and putting it to bed, means that the problem won’t come back….

A3 Problem solving provides the structure for everyone to follow in the organisation.

To take time to ‘sharpen the saw’ and address problems properly. To provide the work around, the fix and short and long term plans to keep the problem away for good.

Creating Problem Solvers

The A3 problem solving process also helps people and teams work together, to provide in-depth, objective problem solving.

It helps create problem solvers in the business, who actively go out to address root causes of problems, which arise every day.

A3s are also good for a multitude of things, like:

- Problem Solving

- Proposing Improvements

- Standardising processes

- Planning

- Reporting

- Reflection and coaching

- Project Management

- Change Management

- Alignment and Agreement

- Organisational Development

- Developing people

The A3 Problem Solving Structure

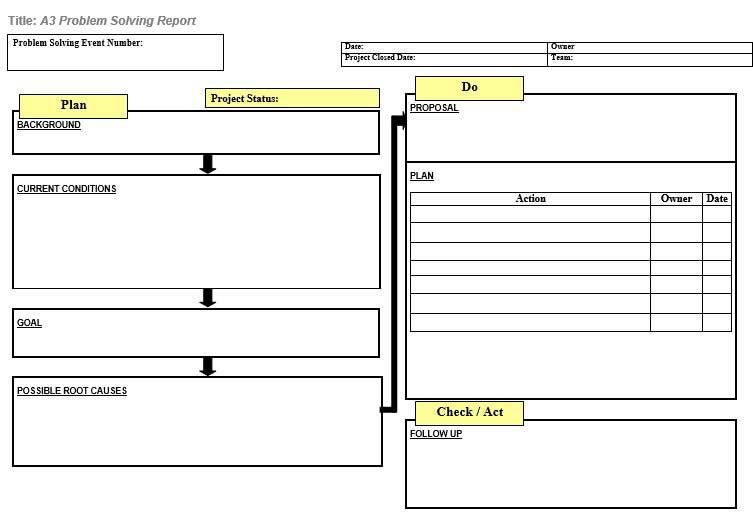

A typical A3 Problem Solving Template has 5 steps or phases to it:

- The problem definition and description

- The Problem Analysis

- The Implementation Plan

- The Results of that Implementation

- The next steps

All in one template. All wrapped around the PDCA model.

Think of the A3 problem solving template of having two key sections:

On the left side, there’s the current state.

What’s happening right now?

What’s the problem?

What’s the root cause?

What do you need to do right now to minimise the impact of the problem?

These are things that take a bit of insight, and data gathering.

2 Sides to an A3 problem solving form

They provide a clear understanding of what the problem is, why it’s important and what the data says.

On the right side of the A3 problem solving form is the future state. This identifies what the proposed improvements are; what the long and short term actions are and any follow up tasks to ensure the problem has been tackled for good.

This structure allows everyone to follow the plan do check act process in a standard way, every time.

Here’s A3 Problem Solving in a Little More Detail

Background:

Enter information as to what’s going wrong, what’s the reason you’re focusing on this problem and how important it is to the business.

Current Situation:

Now enter details of the current problem. Use data to support the statement. What exactly is going wrong? When, and where is it happening?

Go and look at the problem happening at source and get as much information to support your current state analysis. You don’t have to write any detail in here. It could all be diagrams or a process map.

Pictures paint a thousand words.

Target / Goal:

Now it’s time to be totally clear of what should be happening. Add details as to what should change for the better. This could be time, speed, productivity, or any measurable state.

This is what success will look like when the problem has been eliminated.

Again, pictures and diagrams are often chosen over paragraphs!

Possible Root Causes:

It’s now time to delve deeper and identify a possible root cause, using your knowledge from the data analysis and observations.

This process is normally conducted using brainstorming to identify the possible root causes; Conduct 5 whys analysis and then get to the root cause.

Other tools can be used, as long as time is spent in this section to identify root causes, using both inductive and deductive reasoning. (That means using opinions based around solid facts and data).

Countermeasures:

This is the point where you do two things:

Step 1: Identify the most appropriate temporary measure. This is the action that you need to take to minimise the impact of the problem. Often, it’s the thing you need to do to protect the customer, and stop the knock-on effect of the customer experiencing any pain or discomfort from the error caused.

it’s the thing that you need to do to limp through whilst you’re analysing the problem in greater detail and putting the next step in place…

Step 2: Identify the long-term countermeasure. These are the actions that’ll eliminate the problem. They’re the things you need to do to fix it permanently.

Implementation:

This is the action plan. It’s the doing part, and ensures that the countermeasures and improvements are enacted and completed.

The basic rule of creating actions is to answer this simple question: For each action item, answer, who is doing what by when.

Note that every action has an owner and a clear timescale of completion.

Follow Up:

This last section is about following up. It’s the ‘Check’ and ‘Act’ stage of the PDCA model.

Pointers to answer are:

- Are there any unresolved issues that need addressing?

- How will you check the effects of your efforts? And when can you go and see these results?

- How will you report your findings and when?

- Did the findings work?

- What needs to be done next?

The important thing is the process that an A3 template takes you through to resolve issues.

It’s also a working document. This means that it’s updated as the project moves forwards and unfolds. And so, it gives a story of progress.

What’s important is not what the A3 problem solving report looks like, but the process you’ve gone through to solve the problem.